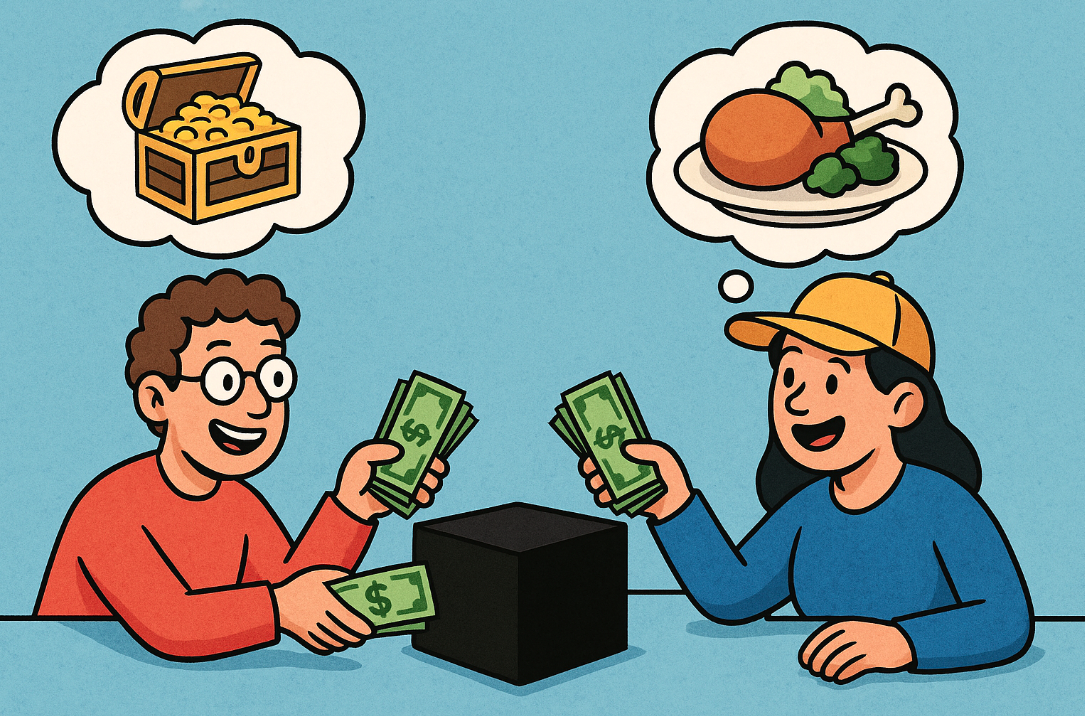

“Technology is the solution! What’s the problem?” This is the approach I have often seen in the tech world, where innovation oscillates between invention and application. Testing new developments is essential: without experimentation, no use cases will ever see the light of day. This is how major advances emerge—from the web, invented to connect researchers, to the 3D printer, which has become a tool for local autonomy.

But let’s be clear: if a technology ends up becoming established, it is always because it meets a real need. Its existence alone is not enough to give it value.

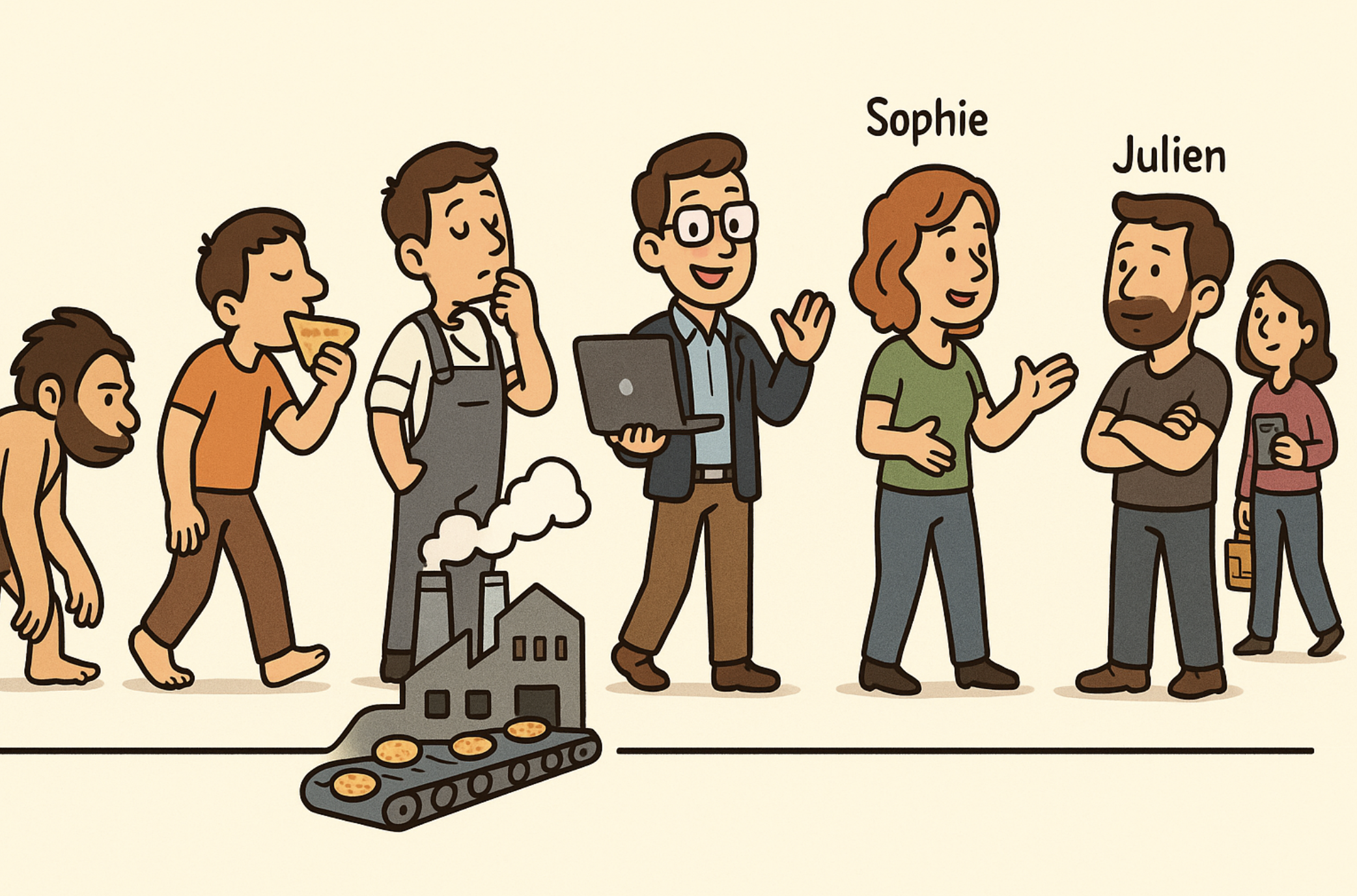

Machines are used in a traditional way before being industrialized

What we are experiencing today with artificial intelligence is reminiscent of what humanity has already gone through during the industrial revolutions. What machines bring to intellectual professions today, mechanization once brought to manual professions. Take the example of the automobile: at the end of the 19th century, cars were built by hand. Each model was unique, designed by highly skilled workers. Then, with the rise of internal combustion engines and machine tools, the industry sought to produce faster and cheaper. But the transition did not happen simply by replacing craftsmen with machines.

A new mode of organization had to be invented to make the transition from craftsmanship to industry: the standardization of parts, the division of labor, and the assembly line, popularized by Henry Ford in the early 20th century. But before this organizational revolution, machine tools already existed. As early as the 19th century, the mechanical lathe, the milling machine, and the drill press appeared. These innovations made it possible to machine faster and more precisely than the human hand, but they remained confined to isolated workshops, used in a traditional way.

Each factory adapted them in its own way, often for a single product or part. It was only with the standardization of components—interchangeable bolts, common templates, unified measurements—and their integration into coordinated chains that their impact increased tenfold. The machine alone did not bring about the revolution: it was the systemic organization that made it transformative.

Today, we are experiencing the same phase with artificial intelligence. The models exist, as impressive and powerful as the first machine tools were, but they still operate outside of intellectual production lines. Each company is experimenting with its own way of using them, often on a small scale, in a unique context.

Industrialization is the standardization of work before automation

This brings me to a second revolution, often less visible but just as decisive: the managerial revolution.

While the industrial revolution transformed workshops into factories and craftsmen into skilled workers, another transformation was taking shape in parallel: that of the organization of work. Large-scale production required finding the right value chain, i.e., the most efficient way for machines and humans to work together to deliver a compliant product in a reliable and repeatable manner.

Take the example of the Manchester spinning mills in the mid-19th century. Mechanical looms ran day and night, powered by steam. But the first factories encountered a recurring problem: unexpected stoppages, bottlenecks, and variations in quality. It was not enough to have the best machines—they had to learn how to make them work together, to synchronize the flow of materials, energy, and labor.

This necessity gave rise to the managerial revolution: the invention of the first foremen, control routines, dashboards, and later, Taylor’s scientific methods of work organization. The challenge was no longer just to produce, but to systematize production, to control the unexpected while guaranteeing consistency.

This quest for efficiency, which began in textile workshops, then spread to all industries, eventually becoming the foundation of modern management: a science of coordination between machines, processes, and humans.

The managerial approach itself has undergone revolutions

The first phase of industrial development consisted of accelerating production by applying old methods on a large scale. Automation—or more accurately, mechanization—was initially used to reproduce the movements of craftsmen, but faster and more powerfully.

At the beginning of the 20th century, Henry Ford did not invent the automobile or even the assembly line: he brought together, organized, and systematized existing practices to make them compatible with mass production. In his Detroit factories, each worker performed only one task, each part was standardized, and every second was measured. The intelligence of the system was concentrated at the top: engineers, planners, and supervisors made the decisions; the workers carried them out.

This model led to an explosion in productivity, but it also revealed its limitations: rigidity, lack of adaptability, demotivation of operators, and accumulation of unnecessary stock.

This is where, half a century later, the Toyota revolution came in. In post-war Japan, resources were scarce: production had to be waste-free. The company then reversed the logic inherited from Ford. Rather than concentrating intelligence at the top, Toyota sought to instill it throughout the chain. Each operator could stop the line in the event of an anomaly, suggest an improvement, or test an idea.

This marked the birth of Lean Manufacturing: a system where innovation becomes collective and continuous, where automation is no longer used to execute faster, but to learn faster.

In short, Ford invented mass production; Toyota invented intelligent production.

Artificial intelligence is in its infancy

Today, the potential impact of artificial intelligence and the diversity of tools available are undeniable. However, in most organizations, adoption remains fragmented and localized: we experiment, we launch pilots, we “test to see.” Recent surveys clearly show this paradox: a large majority of companies report using AI somewhere, but many remain stuck at the POC stage and struggle to move to large-scale industrialization.

Take the example of a large international bank: it can deploy a generative co-pilot to assist branch advisors in a pilot country, with measurable gains in terms of request processing time or response quality. At the same time, the rest of the organization—back office, compliance, legacy IT, other countries—remains largely untransformed. The result is islands of productivity rather than an integrated value chain. This type of configuration is now common in cutting-edge sectors (technology, media, telecoms, healthcare, finance), where AI is well established but rarely orchestrated from end to end.

Companies that manage to build real value chains around AI—with reliable data, models operated in production, adapted processes, and impact indicators—already exist, but they remain in the minority. Among them are digital giants and a few manufacturers or scale-ups that are highly focused on the subject, rather than exclusively “small structures.”

For large groups, several factors are slowing down widespread adoption: organizational inertia, legacy systems that are difficult to adapt, difficulties in demonstrating business value, a shortage of skills, and Conway’s famous law, according to which products end up reflecting the structure of the organization that designs them. Fundamentally transforming practices, decision-making flows, and responsibilities carries a real risk to product quality and operational stability, especially if it is done too quickly.

In practice, the integration of artificial intelligence in many companies today involves localized experiments within certain teams or functions: one use case in customer relations, another in marketing, and a third in IT. These initiatives are not always part of a unified architecture and governance, nor do they fit into a true vision of industrialization (data platforms, MLOps/ModelOps, common standards, systematic impact measurement). The next step is no longer just to multiply the number of pilots, but to connect these islands to create a coherent value chain aligned with the company’s strategy.

The impact factory: Standardize, Optimize, Automate

We are not yet at the point of full AI industrialization—that is, the moment when the technical building blocks (algorithms, platform, data), uses (high-impact use cases), and processes (governance, operation, measurement) align to deliver reproducible, measurable, and integrated value production across the organization. A study by Wavestone points out that “most POCs remain stuck due to a lack of pipeline, governance, or business case”: AI must be treated as an industrial asset, not a gadget.

The real revolution therefore lies not only in the sophistication of the model itself, but in how we reshape the organization of work around it. Because technology is never the starting point: it responds to a need, a context, a situation. Applying AI “for the sake of AI”—for example, automatically sorting applications without addressing biases in the process—can produce the opposite of the desired effect: technology amplifies what it touches; a clear system becomes more efficient, while a confusing system becomes uncontrollable. This observation is echoed in the work of Gartner: “The productivity promised by genAI depends on user experience and the complexity of the function.”

Players who have not yet integrated recent managerial revolutions—lean management, agility, continuous improvement—risk being left behind. On the other hand, technology companies that already combine these practices are in a position to place AI precisely where value is most expected, where bottlenecks are most critical. A study shows that the joint integration of lean, agile, and advanced technologies is correlated with greater performance improvement.

The concept of an “impact factory” is defined in this sense: we start with the problem before the solution. We observe the field, formulate hypotheses, test on a small scale, and then roll out production. Example: in the financial services sector, a major bank implemented an AI co-pilot for advisors, piloted in a single region, with KPIs for reducing response time and increasing customer satisfaction; this model is then extended, conditional on the industrialization of data, governance, models, and operations.

It is this iterative approach—rooted in real needs and focused on impact—that transforms technological tools into levers of impact rather than generators of complexity and chaos. To achieve this, companies will need to:

- define high-potential use cases and prioritize them according to value and feasibility;

- build an “AI factory” that standardizes components (data, models, platforms) rather than recreating them ad hoc each time.

- implement governance, indicators, and a culture that treat AI as an industrial asset (reliability, measurement, return on investment).

- align managerial practices (lean/agile) so that each team can “think value,” minimize waste, and learn continuously.

Otherwise, the proliferation of isolated AI initiatives without connection, vision, or industrialization risks generating not a value chain but a constellation of experiments—interesting but not very productive on a large scale.

Author of Impact Factories / Co-founder of Shy Robotics and Product Whys / Head of Product at Dassault Systèmes / Engineer passionate about innovation and entrepreneurship

Full bibliography here